API Oil Well Drilling PDC Drill Bit & Gas Well PDC drill Bit

PDC bit is a drilling tool commonly used in geological drilling industry.The PDC drill bit are designed professionally for different formations to meet with various drilling characteristics.ShineNor provides Matrix-body drill bit ,Steel body drill bit , Matrix core drill bit.

Product Description

PDC drill bit is a kind of full face drilling bit. It is mainly used for coal mining, oilfield, water conservancy and hydropower, construction of road and building. Glorytek has been in drilling field for decades, and we can offer PDC bit with various sizes and specifications.

Technical Parameter

Bit Type | 6" | 8-1/2" | 8-1/2" | 12-1/4" | Bit Type | 17-1/2" GM1606T |

IADC Code | M423 | M432 | M323 | M432 M332 | IADC Code | M323 |

Blade | 5 | 6 | 8 | 6 | Blade | 6 |

Cutter Size (mm) | Φ13 MM | Φ16 MM | Φ13 MM | Φ16MM | Cutter Size (mm) | Φ16MM;Φ13MM |

Nozzle Qty/Type | 5 | 13.2 | 9.6 | 30.78 | Cutter Qty | Φ16×58;Φ13×81 |

Nozzle Qty/Type | 3NZ | 6NZ | 4NZ | 6NZ | Nozzle Qty/Type | 8NZ |

Gauge Length | 1.5" | 2.2" | 2" | 2.5" | Gauge Length (mm) | 110 |

Connection | 3-1/2" API REG | 4-1/2" API REG | 4-1/2" API REG | 6-5/8" API REG | Connection | 7-5/8" API REG |

Make up Torque(KN.m) | 10.4~11.4 | 24.1~26.5 | 24.1~26.5 | 51.7~56.9 | N.W./ G.W.(KG) | 338/388 |

Rotary Speed(rpm) | 60-260 | 60-260 | 60-260 | 60-260 | Nozzle Size (inch) | 10/32 |

Weight on Bit(KN) | 8-50 | 20-100 | 20-100 | 30-140 | Rotary Speed(Rpm) | 60-260 |

Max.WOB(KN) | 90 | 130 | 130 | 180 | Weight On Bit(KN) | 30-200 |

Flow Rate(lps) | 10-30 | 22-35 | 22-35 | 38-70 | Max.WOB (KN) | 240 |

Flow Rate(lps) | 45-80 | |||||

Above are regular sizes for your reference. Size can be customized as per your requirement. | ||||||

Features

1) The whole material of the drill bit is made of high quality alloy to protect and reduce the wear of the bit.

2) We studied the welding technology of Varel International to further improve the bit quality.

3) Using FireStorm technology to improve the previous prop technology, improve wear resistance and thermal stability.

PDC bit use precautions

1. Before the drill bit is down, it is necessary to confirm that the bottom of the well is clean, no sand, no metal falling.

2. Check if the thread connection thread of the PDC is intact and the nozzle installation is intact.

3. Before drilling, you should avoid the pressure too much and prevent the bit from falling.

4. The last single root should have a large displacement starter turntable, and draw the eye to the bottom of the well. Fully wash the well to prevent the cuttings from clogging the nozzle. It should be gently pressed and slowly contacted to smoothly contact the bottom of the well, with small drilling pressure, low rotation speed, large displacement and small torque operation.

5. The bottom hole shape is 40-60RPM, and at least 30 minutes.

6. Refer to the recommended parameters of the drill manual, and determine the drilling pressure and speed in combination with the actual conditions of the formation.

7. The operation should be smooth during the drilling process, and the drill should be evenly distributed.

8. If it is found that the drill bit does not have a footage, the pump pressure is obviously increased or decreased, the connection speed is suddenly decreased, and the torque is increased.

Categories

- Inside Blowout Control Tools

- Subs &Tool Joints

- Downhole Drilling tools

- Swivel joint/Hose loops/Union/valve/oilfield hose

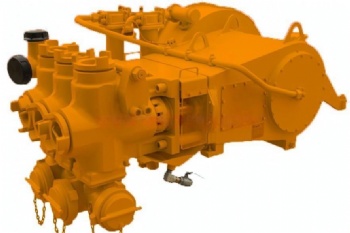

- Cementing fracturing plunger pump and spare parts

- Sucker Rod and Sucker Rod Coupling

- Wellhead Equipment and Tools

- Fishing & Milling Tools

- Oil Country Tubular Goods

- Drilling jars

- Cementing tools and Casing accessaries

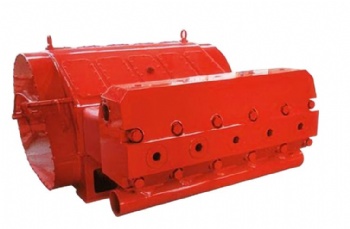

- Mud pump spare parts

Contact Us

- +86-17611660323

- info@snpetro-equip.com

- +86-17611660323

- +86-17611660323